NDW Rollers

NDW a Dutch company that manufactures

high quality rollers In Hungary, our company provides executive representation. With full knowledge of the production processes and product sales philosophy of the NDW the best solution when selecting rollers, motor rollers, and motor controllers for material handling systems.

Excellent value for money , and we also provide system development and technology selection support to create the best possible material handling system.

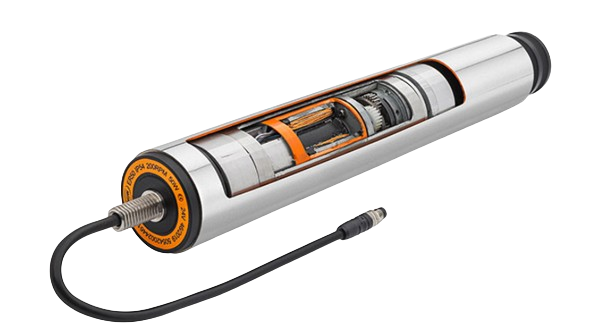

Motorized rollers

NDW motorized rollers are high-performance adjustable brushless motorized rollers . An excellent option for driving conveyor systems, which can be regulated and controlled with NDW's own developed motor controllers. The systems can be built with a plug-in solution, so installation and operation are simple and efficient.

24 V motorized roller

Brushless motors are produced in 50 and 60 mm sizes. They are also available in galvanized and stainless steel versions, and the torque can be transmitted through different drive heads or in the grooves formed on the casing.

Main features

Supply voltage: 24V DC

Operating current consumption: 2A

Starting current: 2A

Power: 50W

Operating conditions: 0°C – 40°C humidity-free environment

Motor connection head: stainless steel hex head 11m, fixing M12

Cylinder diameter: Ø50mm x 1.5mm, galvanized or stainless

Protection : IP54

Noise level: 55dB

Minimum length: 275mm installation with poly-V head

Compatible drive controllers: BC 50, BP120

Connector type: M8, 6 pin, 900mm long

Jam protection: yes Overvoltage

protection: yes

Speed ranges, torques: 0.05-0.25m/s 4.07- 2.57Nm (6.88Nm starter)

0.1-0.5m/s 2.11-1.26Nm (3.84Nm trigger)

0.2-1m/s 1.03-0.55Nm (2.09Nm trigger)

0.6-3m/s 0 .3-0.18Nm (starter 0.63Nm)

Possible drive designs: with round belt in the cylinder liner groove,

double round belt head

Poly-V belt head

Ribbed belt head

Double sprocket head

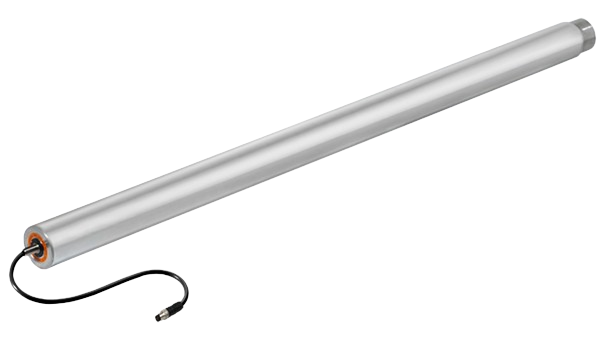

24V pallet motorized castor

NDW pallet motorized castors are also brushless DC motors. Integrated into the standard ø63.5 / 70/80/89 mm NDW roller casing, they are an excellent alternative to driveless rollers in conveyor systems. (max. speed 0.35 m / s).

Main characteristics

Supply voltage: 24V DC

Operating current consumption: 2A

Starting current: 2A Power

: 50W

Operating conditions: 0°C – 40°C humidity-free environment

Motor connection head: stainless steel hex head 11m, fixing M12

Cylinder diameter: Ø63.5mm standard version (versions 63.5, 70,80,89mm)

Protection: IP54

Noise level: 55dB

Compatible drive controllers: BC 50, BP120

Speed ranges, torques: 0.06-0.45m/s 4.1-2.6Nm (6.9Nm starter)

0.04-0.23m/s 6.5- 4.9Nm (12.7Nm starter)

0.02-0.14m/s 11.0-7.8Nm (19.4Nm starter)

Possible drive designs: Poly-V belt head, Double sprocket head

BC50

The simplest unit of the NDW motor controllers is the BC 50 controller, which is used to control one motorized roller. There is no sensor connector, it is only used to control the motor by external control signals. Its primary function is speed and direction control.

On the controller, the running direction of the motorized roller is possible through a user-friendly interface. The settings can be changed using this graphical user interface (LCD display) and simple buttons, so there is no need for dip switches. The external control signal is possible with simple I/O control using a PLC.

Main features

– User friendly interface

– Standalone operation or simple I/O control

– Motor E-cylinder induced overvoltage protection

– Shutdown protection

– Energy efficient and low starting current

– Speed and fault indication on GUI

– PNP and NPN compatible. It can be configured in the settings.

The BC50 controller can be controlled in two modes:

Manual and I / O mode. In manual mode, the user can operate the entire E-roller (Running, Direction, Speed) simply using the integrated buttons and the control interface. In I/O mode, the operating settings of the E-roller can be controlled via external I/O.

BP120

The BP 120 controller has two motor controllers with sensor integration for complex programming and system communication. Thanks to its built-in transformer, it can be immediately connected to 230 V, which is why it is an excellent plug and play solution. Suitable for larger systems, it works in stand-alone mode and intelligent mode.

The BP120 IP65 controller is used to drive two NDW E-rollers. Thanks to the two motors and sensor connectors built into the base housing, it can be used in a wide range of material handling and intralogistics applications. It can be immediately switched to 230 V with the help of a transformer integrated in the control housing, which makes it possible to create a simple and easy-to-build application, it is a plug and play solution.

Operating modes, basic functions:

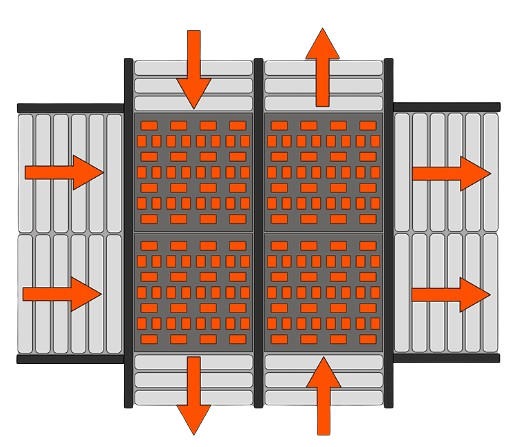

Pressure-free blocking

The BP120 provides a completely independent Zero Pressure Accumulation (ZPA) operation. It is possible to move material without physical congestion by touch. The conveyor system consists of segments, each individual unit with its own sensor, a motorized roller and several driven rollers. The motor controllers communicate directly with each other, thereby knowing their environment and the status of each conveyor module.

Delay and Time Limits

The controller has several delay functions and time limit controls. Due to the design of the menu system, they can be easily customized. For example: start-up, transfer waiting, operational delay of sensors. Customizing the menu system allows you to run the system easily.

Train mode

A complex control network can be created by stringing the motor controllers together, so that even the motors can behave in the same way. This is a huge advantage in the case of integration of conveyor systems with long and simple operation. Here, you only need to set up a master BP120 controller, the rest follows its properties.

Anti-jamming protection

When the motor detects a jam, the anti-jamming protection of the controller is activated to protect the motor. The controller tries to restart the stuck motor or segment a couple of times. In case of engine shutdown, the controller indicates an error on the display and gives an error signal.

Overvoltage protection

The BP120 controller is equipped with a protection. To protect motorized rollers against induced overvoltage when the system is operating in generator mode.

Directional switches

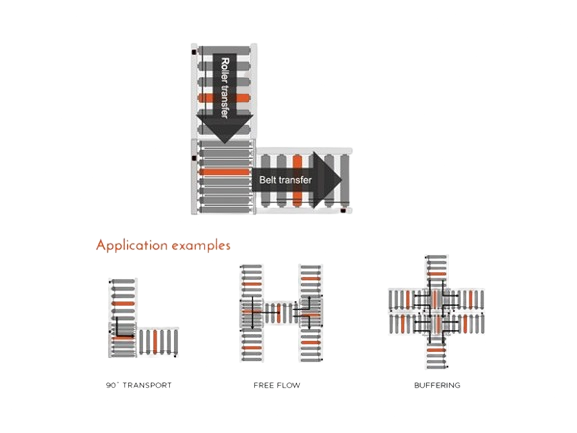

90° direction changer

The NDW CSD is a simple transverse material handler. The classic 90° direction changer can be easily integrated into conveyor systems.

Main features

Installation height: 213 mm

Depending on the size of the product, up to 1000 packages/h

Available lengths: 550 (min) / 850 (max) mm

Available widths: 500 (min.) / 750 (max.) mm

Minimum product weight: 50 gr.

Max. product weight: 30 kg.

24 V logic and drive system

Light, robust aluminum structure

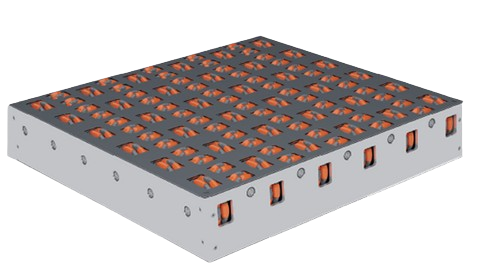

Cross sorter

Depending on the product size and weight, the cross sorter provides a capacity of more than 2,000 packages/hour, the innovative design enables 360-degree sorting solutions. The sorter can be controlled with NDW's range of controls, but is not limited to NDW tech. The modular design allows the use of third-party controllers.

Main features

Built-in height: <200 mm

Depending on the product size, with a speed of up to 2,500 packages/h

Drive mechanism: high-grip PU omni wheels

360-degree sorting solutions

Module sizes: 400×400, 600×600, 800×800 mm

Minimum product size: 100×100 mm

Maximum product size depending on the number of modules

Available speeds: up to 1.5 m/s 0.5 m/s

24 V logic and drive system

Minimum product weight: 50 gr.

Max. product weight: 40 kg

Light, robust aluminum structure

High-speed sorter

The high-speed sorter is a

modular sorter concept that is the most versatile in its category.

of the product , it can sort up to 6,500 packages per hour

. It has a 24 volt drive in each reel that

can be serviced by a "quick release" operation. The sorter can be controlled with NDW's

range of controls, but is not limited to NDWs tech. The

modular design allows

the use of third-party controllers.

Main features

Installation height: 200 mm

Depending on the product size, at a speed of up to 6,500 packages/h

Disc diameter: 184 mm

Between -90 and +90 degrees in 0.3 seconds

Available lengths: 200-400-600 mm

Available widths: 400-600-800- 1000 mm

Minimum product size: 100×100 mm

Maximum product size a depending on the number of modules,

24V logic and drive system

Minimum product weight: 50 gr.

Max. product weight: 40 kg

Light, robust aluminum structure